Calibrating a course of meter entails adjusting its settings to ensure correct and dependable measurements

Gather Necessary Tools and Equipment:

The course of meter's guide

Calibration standards (calibration gases, weights, etc.)

Multimeter or different calibration devices

Screwdrivers or other tools for adjustments

Review the Manual:

Familiarize your self with the producer's instructions and specifications.

Perform a Pre-Calibration Check:

Ensure that the method meter is clear and in good condition.

Check for any visible harm or wear.

Prepare Calibration Standards:

If relevant, prepare the calibration standards required for the particular measurements your process meter is designed for.

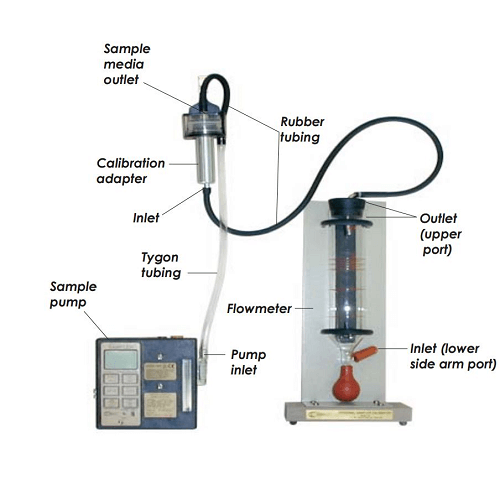

Connect the Meter:

Connect the process meter to the calibration instrument and the calibration standards.

process meter calibration services :

If your meter has a zero adjustment, modify it to learn zero when there is no input sign.

Adjust Span (Full-Scale):

Adjust the span management to make sure that the meter reads accurately on the full-scale measurement level.

Verify Intermediate Points:

Check and adjust intermediate factors if needed, making certain accuracy throughout the entire measurement vary.

Stabilize Find more info :

Allow the meter to stabilize for a enough interval after changes to ensure correct readings.

Perform Functional Tests:

Check the meter's performance by applying recognized inputs and comparing the readings to the expected values.

Document Calibration Results:

Record the changes made, calibration standards used, and the outcomes obtained.

Label Calibration:

Label the method meter with the calibration date, technician's title, and any other relevant data.

Final Verification:

Double-check the calibration by evaluating the readings with identified standards.

Finalize Calibration:

If the meter meets the required accuracy criteria, finalize the calibration process.

Create a Calibration Schedule:

Establish a daily calibration schedule based on the manufacturer's recommendations and the usage environment.

Remember that security is a precedence in the course of the calibration process. Follow safety guidelines, and in case you are unsure about any steps, consult the producer's documentation or seek help from a certified technician..